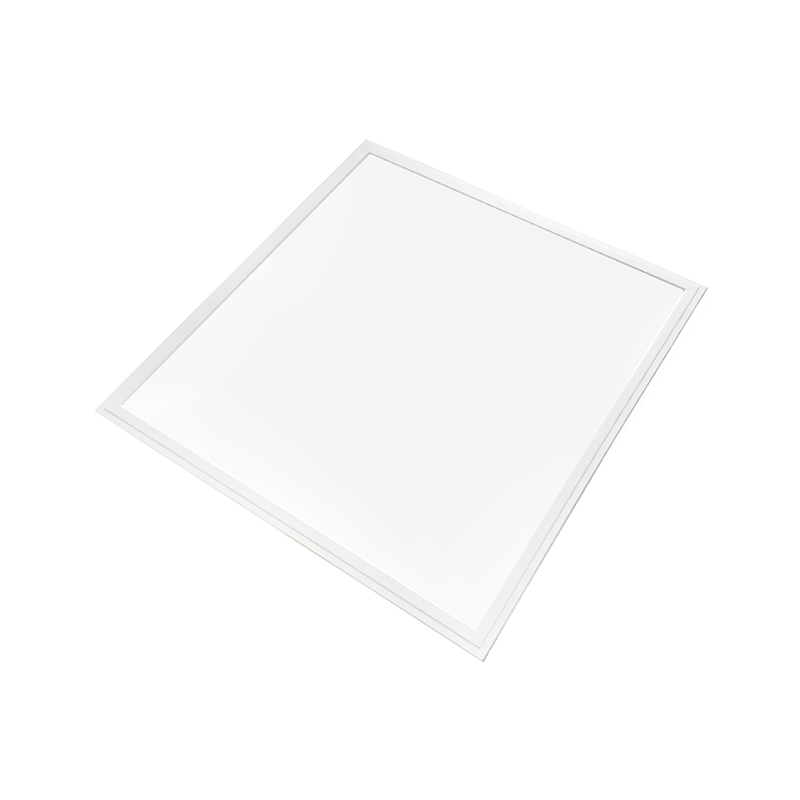

In modern lighting applications, LED back-lit panel lights, with their ultra-thin design, uniform light, glare-free operation, and high energy efficiency, have long since moved beyond office spaces to more complex and varied usage scenarios.

- +86-13728765409

- admin@tsongledlighting.com

- 3rd-5th Floor, Building 15, Xinlishi Technology Park, No. 2, Lefeng 8th Road, Henglan Town, Zhongshan City